pierre de granit blanc cristal

- moulin 224 billes bekerja

- l oklahoma est le concasseur de pierres

- chauvine ecran et cribles vibrants pdf

- concasseur maker pierre

- des moyens de minimiser l'impact des poussières de cimenterie

- Épaississant Synthétique Dans Le Processus De Fer

- pierre dolomite alunite

- Concasseur à mâchoires Otsukaharga

- ressorts de compression de tamis

- petits fabricants de broyeur à boulets en afrique du sud

- pièces d usure des concasseurs

- usines de broyage ciment doccasion a vendre

- doublure plaque de broyeur à boulets

- impact de l extraction et du raffinage du feldspath

- repertoire des fabricants de concasseur pali de marwar

Message en ligne

Meilleur concasseur et crible, fabricant de concasseur Sanyyo

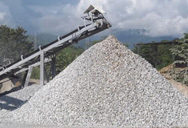

Sanyyo, un célèbre fabricant de machines de concassage de pierres qui se concentre sur le concassage et le criblage, l'équipement de concassage, a gagné des milliers de clients mondiaux. Fabricant exportateur de concasseur de pierre installation complète de concassage et de criblage de Shanghai, en Chine.

Comprendre les concasseurs de granulats : Types, fonction et

2023年10月21日 Ils ont pour tâche essentielle de réduire la taille de ces matériaux afin de faciliter le transport, d’accroître l’efficacité et de répondre aux exigences des projets de construction. Le fonctionnement d’un concasseur de granulats implique l’introduction du matériau dans la machine par l’intermédiaire d’un alimentateur vibrant ou d’une bande transporteuse.

Concasseur de mâchoire mobile compact RUBBLE CRUSHER

Concasseur de mâchoire mobile compact RUBBLE CRUSHER. La référence des produits de la construction 30 000 produits - 5 000 ... TROUVEZ DES FABRICANTS ET DES PRODUITS. Besoin d’aide pour trouver vos produits ? Faites appel à nos experts ! Déposer votre demande.

AFDICQ - Association des fabricants et détaillants de l'industrie de ...

L'AFDICQ, le partenaire de l’industrie québécoise de l’armoire de cuisine . L’Association des fabricants et détaillants de l’industrie de la cuisine du Québec a pour but de promouvoir le développement des entreprises québécoises spécialisées dans la conception et la fabrication d’armoires de cuisine, de salle de bain et de meubles sur mesure.

Les différents types de concasseurs suivant vos besoins

2021年9月24日 Les concasseurs à cône sont utilisés dans les étapes de broyage secondaire, tertiaire ou quaternaire. Ceux-ci sont dotés d’ arbre fixe. La roche est brisée entre la tête tournante de la machine ou mâchoire fixe et du bol ou mâchoire mobile. Un concasseur à cône est conçu pour concasser des matériaux généralement de 100mm à 200mm.

répertoire des concasseurs de pierres

2022年9月16日 Le répertoire des Fabricants de concasseurs à vendre des pierre de granit mines vente en Inde fabricants,louer. mines de charbon dans le rajasthan – Concasseurs-Broyage Dans les mines de charbon en Inde – . est un projet de Suzanne Lee sur le travail des enfants dans les mines de

ARCHIVES NATIONALES FONDS DE LA REUNION DES FABRICANTS DE BRONZES ...

106 AS 1-50 : Réunion des fabricants de bronzes devenue Chambre syndicale des fabricants de bronzes (1817-1954) 106 AS 1-2. Statuts 106 AS 3. Membres 106 AS 4-19. Administration 106 AS 20-44. Financement et comptabilité 106 AS 44-50. Activités 106 AS 51-55 ...

Concasseur primaire, Unité de concassage primaire - Tous les ...

Fabricants. B; BAIONI CRUSHING PLANTS SPA (1) bccm (1) Binder+Co AG (2 ... 600 mm ±10% Type de concasseur - - : Concasseur à mâchoires primaire série BCK Ouverture d'alimentation ... Ajouter au comparateur Retirer du ... Les concasseurs à mâchoire sont l’un des types les plus préférés de concasseur... Ajouter au comparateur Retirer ...

Concasseur de pierre, gravats, béton, parpaings, roche

Pour valoriser vos matériaux de démolition, gravats, fouilles, pierres naturelles, roches, tuiles, déchets de marbre, parpaings, briques. Le concasseur à mâchoires est conçue pour réduire les grosses roches en petites pierres, gravier, ou poussière de roche. Pour le recyclage des matériaux de démolition.

Répertoire de la protection incendie AEAI - Sitename

Le catalogue suisse des produits conformes aux prescriptions de protection incendie le plus complet et le plus actuel. Fabricants, distributeurs et entreprises spécialisées. Autorités de protection incendie, responsables de l’assurance qualité, projeteurs et maîtres d'ouvrage.

Concasseur à mâchoire, Unité de concassage à mâchoire - Tous

Un concasseur à mâchoires est une machine de broyage qui utilise l'énergie mécanique pour briser des blocs de pierre en blocs de taille inférieure de granulométrie déterminée. Les concasseurs à mâchoire imitent le fonctionnement d'une mâchoire en écrasant la pierre entre une plaque fixe et une plaque mobile soumise à un mouvement alternatif.

Les membres MMCQ sont des manufacturiers payant une

Entrez vos mots-clés, ceux-ci peuvent être retracés grâce au moteur de recherche: Produits; procédés de fabrication; certifications; entreprises; Votre entreprise fait partie du répertoire, mais sa fiche est incomplète? Contactez-nous ([email protected]). Pour voir la liste de toutes les entreprises, n’inscrivez rien et cliquez sur Rechercher.

association de concasseur de pierre pali

Le concasseur J-1170 inclut un alimentateur vibrant . Read More annuaire des fabricants de concasseurs de pierres pali marwar. pali association pierre concasseur - penzion-zubejda. Concasseur Pali - tegels-terrasoverkappingen» pali stone crusher association » extec c10 crusher for sale » Read More Amazon : Concasseur Pierre. Demande En Ligne

Concasseur secondaire, Unité de concassage secondaire - Tous

Un concasseur est une machine de broyage qui utilise l’énergie mécanique pour briser des blocs de pierre, de béton, ou d’autres matériaux de construction, en blocs plus petits de granulométrie déterminée. Ils sont notamment utilisés dans l’industrie minière pour réduire la taille des blocs de minerai et faciliter leur traitement.

Codes d’usages et Répertoire - Alliance 7

une histoire et une identité commune, que les « Fabricants de Biscuits Gâteaux de France » ont à cur de préserver. A. Objectif du document L e Syndicat des « Fabricants de Biscuits Gâteaux de France », depuis sa création en 1945, s’est engagé à protéger les dénominations traditionnelles de biscuiterie et pâtisserie.