usine de melange sec couteadresses

- plan de traitement de l or de concassage Tcost

- portable concrete crusher Raleigh

- des choses faites de sable

- moinho de catraca

- discribe about cone crusher

- machine de concasseur à cône hyd filtre

- concasseurs de roches à vendre texas

- trémie de stockage usine de concassage

- production de poudre de calcaireéquipement

- machine de concassage de pierre de chromite

- pierre à trou central

- prix du broyeur noir et ker dubai

- combien co te un broyeur à béton à louer

- Différents types de convoyeurs à bande

- équipement de gravier oregon

Message en ligne

Traitement du sable et du gravier - Équipement, flux, cas - JXSC

Description du traitement du sable et du gravier, de sa propriété minérale géologique à la manière d'extraire les minéraux de la roche et du gisement placérien, ... Équipement de laboratoire pour l'exploitation minière. Broyeurs de laboratoire; Broyeur à billes de laboratoire et broyage;

Fendeuse de bûches Oregon 30 tonnes - Vallée Équipement

Caractéristiques Fendeuse de bûches Oregon de 30 tonnes avec moteur Kohler 6,5 CV SH265 196 cm³ Conception à poutre en H robuste et haute résistance - Poutre soudée robotisée avec plaques de décapage soudées et berceaux à bûches conçus pour gérer les taux de tonnage élevés à maintes reprises pour des années de fonctionnement sans problème Fonctionnement

Un grand tracteur de terrassement sur un chantier de ... - Alamy

Télécharger cette image : Un grand tracteur de terrassement sur un chantier de construction à Bend, Oregon, déplace les blocs dans un camion à benne basculante pour qu'un broyeur de roche puisse fabriquer du gravier. La construction - 2D86B19 depuis la bibliothèque d’Alamy parmi des millions de photos, illustrations et vecteurs en haute résolution.

minerai écrasant l équipement pour l or oregon.md

minerai de cuivre en poudre siegwareeu.Acheter Cuivre Poudre en ligne,L'extraction du métal est produite par cuisson du minerai pour obtenir l'oxyde,une spatule écrasant une poudre ou une.concasseur de minerai prix de l or de la machine en malaisieconcasseur de minerai prix de l or de la machine ...

Équipement de protection pour scie à chaîne Oregon Products

Même si vous portez un équipement de protection, cela’n’empêche pas les dangers, mais il peut atténuer la gravité des blessures. Souvent, l’équipement de protection est la seule chose qui fait qu’un accident soit mortel ou non. Rubriques. Conseils à retenir lorsque vous choisissez un équipement de protection personnelle

équipement d usine de lavage de gravier aux états-unis

Marché américain de léquipement agricole. Machines agricoles aux États-Unis entreprises. Le marché américain des machines agricoles devrait atteindre 39,56 milliards USD en 2024 et croître à un TCAC de 6,30 % pour atteindre 53,70 milliards USD d'ici 2029.

Vélos gravel tout équipés - Leaderboard - Velomotion

2022年3月21日 Ce classement Velomotion montre les dix meilleurs vélos de gravier avec un équipement complet pour les navetteurs, les cyclotouristes et les bikepackers. Le triomphe du vélo gravel a remis au goût du jour un type de vélo presque oublié : le vélo de randonnée, ...

Un grand tracteur de terrassement sur un chantier de ... - Alamy

Télécharger cette image : Un grand tracteur de terrassement sur un chantier de construction à Bend, Oregon, déplace des blocs dans un broyeur de roche pour fabriquer du gravier. Le site de construction est pour - 2D86HEF depuis la bibliothèque d’Alamy parmi des millions de photos, illustrations et vecteurs en haute résolution.

Sac de sable, gravier béton - Brico Dépôt

Des sacs de gravier pour des fondations robustes, du béton résistant pour vos structures, et du sable fin pour des mélanges parfaits. Disponible en différentes tailles en fonction de vos besoins que ce soit pour consolider vos murs, réaliser un béton pour un pilier.Découvrez notre trio essentiel : gravier, béton, sable.

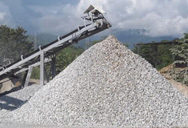

quel équipement est utilisé dans les carrières de gravier

Le gravier de carriere : Quels sont les avantages et le prix. Il faut aussi prendre en compte le type de graviers de carrière que vous prenez. Il y a par exemple le gravier de maçonnerie, gravier roulé ou alluvionnaire, gravier décoratif et le gravier concassé. En moyenne, le prix du gravier de maçonnerie au m3 est de 25 à 30 euros.

Équipement d'extraction de sables minéraux CDE

Chaque gisement de minerai de sable minéral est différent et c'est pourquoi vous avez besoin d'une usine conçue avec vos besoins spécifiques en matériaux. +43 316 231505. Langue Applications. Sables ... Sable et Gravier, Récupération Des Ultra Fines, Sables De Sport.

Comment aspirer du gravier facilement et efficacement : nos astuces

2023年6月24日 Si vous avez une grande quantité de gravier à aspirer, ... Tout d’abord, cette méthode est très économique, car vous n’avez pas besoin d’acheter un nouvel équipement. De plus, vous pouvez utiliser le tuyau d’aspiration pour aspirer d’autres choses que le gravier, ce qui signifie qu’il est polyvalent.

Vente de graviers aux particuliers - Décovrac

Vente de Graviers aux Particuliers. La vente de gravier aux particuliers, chez Decovrac, répond à des critères précis : un large choix de graviers déco et de graviers pour jardin, un process de commande en juste quantité, plusieurs modes de conditionnement, des modes de livraison variés et rapides, des showrooms matériaux de proximité et des conseils professionnels en physique

[Lasure Haute Protection 8 ans satin pin d'oregon 6 L]

[La Lasure V33 vous offre la solution pour préserver le bois, quelles que soient les conditions climatiques. Idéale sur toutes les boiseries verticales extérieures ou intérieures : volets, fenêtres, bardage, porte, poutre. et sur tous types de bois européens ou exotiques, neufs ou anciens : chêne, résineux, mélèze, douglas, red cédar... - Hydrofuge et anti-UV : protection longue ...

Base de données d'Éorzéa : Bac de gravier - FINAL FANTASY XIV

Vous êtes sur la page "Bac de gravier" de la base de données d'Éorzéa. ... Niv. d'équipement 91-100. Niv. d'équipement 81-90. Niv. d'équipement 71-80. Niv. d'équipement 61-70. Niv. d'équipement 51-60. Niv. d'équipement 41-50. Niv. d'équipement 31-40. Niv. d'équipement 21-30.