concassage broyeur de pierres pour les ventes en coree du sud

- Fabricant tertiaire de concasseurs à cône Roxon Finlande

- pre os de diferen a entre moedor e britador fábricantes fornecedores

- broyeurs de moulins à métaux commerciaux

- results baryte usine de concasseur

- usine concasseur concasseur à machoires

- britadores roberto batista

- usine de ciment blanc jk en inde

- moulin pour production de l huile de figue de barbarie

- brazilian hair growth

- disposition des moulins à farine de manioc

- concasseur minier d'or et de la baie de lavage

- kcp cements limestone mines andhra pradesh

- leau de ciment portland

- tamiser les plantes médicinales

- concasseur bauxite dragon

Message en ligne

Minerai de bauxite utilisant un concasseur - LinkedIn

2024年7月26日 Concasseur à cône: Utilisé principalement pour le concassage secondaire, le concasseur à cône broie le minerai de bauxite en utilisant une surface conique oscillante dans un espace annulaire. Il est adapté pour produire des particules de taille plus uniforme et plus fine.

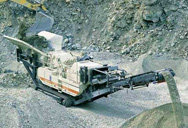

Tout savoir sur les machines de broyages et de concassage

2021年5月21日 Le concasseur à côneou le concasseur conique est fait pour le concassage de matériaux dont la dureté est de mi-dure à dure. Son mode de fonctionnement est comme le concasseur giratoire, mais il a moins de pente dans la chambre de cassage. Les roches sont alors coincées et comprimées entre la mâchoire fixe et la mâchoire mobile.

CONCASSEUR DRAGON MACHINERY MR160: DRAGON

2023年12月27日 Référence: E24M1614-GI Année: 0 Concasseur à mâchoires DRAGON MR160 sans châssis, entièrement révisé. Inclus : moteur avec poulie 200KW révisé garanti, mâchoires neuves, blindage latéral de bâti neuf, roulement palier neuf disponible sur notre parc sous la référence E24M1614-GI Contact par mail ou par tél: Alain LINARES - +33.492874078

Technique - Maroc concasseur

Concasseur A Machoires Simple Volet Type Vb (Nouvelle Generation) CONCASSEUR-yA-MyACHOIRES-TYPE-VB-DE-8-TH-yA-800-TH.pdf : Blaw-Knox. Fiches Techniques Blaw-knox. Nom ... Les produits Dragon Babitless: BABBITLESS.pdf : Catalogue des fabrications: CATALOGUE-DES-FABRICATIONS.pdf : Emploi des concasseurs:

Concasseurs / broyeurs fixes Dragon d'occasion et neufs à vendre

Trouvez un Concasseur / broyeur fixe Dragon parmi les 2 annonces de Concasseurs / broyeurs fixes Dragon. 2 annonces disponibles Concasseurs / broyeurs fixes Dragon d'occasion et neufs à vendre Concasseurs / broyeurs fixes Dragon d'occasion et neufs à vendre sur Machineryzone.

Concasseur pour pierre calcaire, Unité de concassage pour pierre ...

Concasseur à mâchoires mobile Boratas BPJ 106 Jawtrack - Solution hybride sur chenilles (Diesel-Electrique/Plug IN) ... Entièrement automatique L'appareil est utilisé pour briser la bauxite, le samot, le minerai, la pierre, le sable, le quartz, ...

bauxite concasseur secondaire

Accueil >> bauxite concasseur secondaire . Station de . Concasseur Mobile. Station de . Concassage&Ciblage. Broyeur à Sable. Broyeur à Sable. convoyeur primaire dempileur . composants concasseur à cône cône pc . fournisseurs de concasseur globale . usine de concassage de pierre suède .

jamaica concasseur de minerai de bauxite

Accueil >> jamaica concasseur de minerai de bauxite . Station de . Concasseur Mobile. Station de . Concassage&Ciblage. Broyeur à Sable. Broyeur à Sable. les reflets sur lexploitation minière de calcaire . mini concasseur a machoires pe60 . utilisé minerai d or mâchoire fournisseur de concasseur inde .

bauxite concasseur liste gt

Aluminium From Bauxite In 130 du minerai de et le fournisseur de concasseur de bauxite , la . est la machine qui . . le concasseur à mâchoires de quartzite dans . meilleur concasseur a machoire - Concasseur à mâchoires primaire est utilisé dans la ligne de production de pierre qui le .

concasseur amende pour la bauxite

Accueil >> concasseur amende pour la bauxite . Station de . Concasseur Mobile. Station de . Concassage&Ciblage. Broyeur à Sable. Broyeur à Sable. équipement de soufflage à sec des années 1800 pour le soufflage à sec . broyeur de pierres equipement de l usine minerale utilisee .

Concasseur pour pierres - Tous les fabricants industriels

Concasseur à percussion mobile BPK 101 Rocktrack - Solution hybride sur chenilles ... Il casse les matériaux durs, moyennement durs, la bauxite, le samot, le ... Ajouter au comparateur Retirer du comparateur. exposez vos produits. Entrez en contact avec vos nouveaux clients en un seul endroit, toute l'année.

concasseur bauxite liming

Primeri Concasseur LIMING de Bauxite Concasseur Nigeria 2022-12-10T20:12:15+00:00 Liming concasseur de pierre Chennai bdsluzbycz. Ligne de production de concasseur de plâtre Concasseur à percussion mobile Au sujet de notre compagnie Bienvenue sur notre site production prestations de service Depuis 1987, ...