basculer le meilleur dans le monde cheval

- convoyeur a bande mobile

- giratoire et concasseur à cone différence

- moulin de meulage Chine afrique concasseurs de

- convoyeurs et systemes de convoyeurs industriels

- pc x broyeur à marteaux

- moulins de moulin en pierre de basalte antique

- Petit moulin à sable des capacités

- petite concasseur de minerai de iro à vendre en Senegal

- équipements de concassage de béton d'occasion à vendre

- en Indeinstallation de criblage mobiles

- concasseurs 30x42 plus récent broyeur broyeur mobile

- pièces de concasseur à mâchoires hewitt robinson results

- ligne consommation d'énergie de broyage

- broyeur a marteaux 30 cm

- concasseur de gypse bangalore

Message en ligne

Concasseur — Wikipédia

Concasseurs de pierres, XIX e siècle. Photographie par Eugène Trutat, conservée au Muséum de Toulouse.. Un concasseur est une machine conçue pour réduire les grosses roches en petites pierres, gravier, ou poussière de roche. Les concasseurs peuvent être utilisés pour réduire la taille ou changer la forme des déchets afin qu'ils puissent être plus facilement éliminés ou recyclés.

Etude et vérification de choix de concasseur dans une cimenterie

Avant tout, je remercie DIEU qui a illuminé mon chemin et qui m’a armé de courage pour achever mes études. Et « quiconque ne remercie pas les gens, ne remercie pas Dieu» Je remercie fortement mon promoteur : M r AIT HABIB de m’avoir orienté par ses conseils judicieux dans le but de mener a bien ce travail et je n’oublie pas M r le président de jury Mr. DJEZAIRI et le

machine de fabrication de poudre de gypse bangalore

Machine de fabrication de poudre de gypse en Chine Shandong Tengfei Technologie mécanique et électrique Co., Ltd vous donnera une introduction détaillée au contenu de Machine de fabrication de poudre de gypse en Chine, y compris l'objectif, le modèle, la portée, les images, les commentaires, etc. de Machine de fabrication de poudre de

Mini concasseur CR400 CR600 CM Power - Pacamat

Mini concasseur cr400 et cr600 de la marque CM POwer disponibles chez PACAMAT Equipement, ... La solution idéale pour le recyclage de matériaux inertes, de démolition de petites tailles, gravats, fouilles, pierres naturelles, roches, tuiles, déchets de marbre, parpaings, briques.

Concasseur à mâchoires - Concasseur à Mâchoires à Vendre

Les machines de concasseur à roches à mâchoires sont un composant important des installations de concassage et de criblage. Les prix de ces machines peuvent varier selon les caractéristiques technologiques et la capacité de la machine. Un concasseur à mâchoires mobile est une option polyvalente qui offre l’avantage de la mobilité.

Tout savoir sur les concasseurs Hellopro

Vous pouvez l’utiliser pour traiter du basalte, du granite, du marbre, du quartz ou du minerai de fer, selon les besoins de vos petits chantiers. Un concasseur de pierre à percussion, lui, affiche en général un prix compris entre 10 000 et 75 000 euros. Il est capable de traiter entre 10 et 350 tonnes de pierres par heure.

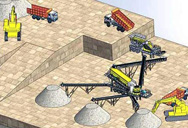

L'exploitation des gisements de gypse Les industries du plâtre

3/ Principe de l’exploitation à ciel ouvert Après avoir décapé la terre végétale qui est mise en merlon en vue de la revégétalisation future, les sables, les argiles et les marnes reposant sur le toit de la première masse de gypse sont extraits à l’aide d’une pelle hydraulique et transportés par des tombereaux pour être mis en remblais et participent au réaménagement du site.

Traitement du gypse - Équipement, flux de processus, cas

Ensemble, ces États représentent environ deux tiers de la production annuelle de gypse des États-Unis. Plus de 30 millions de tonnes de gypse sont consommées chaque année aux États-Unis. Le Canada, le Mexique et l'Espagne sont d'autres producteurs importants de gypse brut. Au total, plus de 90 pays produisent du gypse.

Annonces de concasseur d'occasion à vendre - Mascus France

Ci-dessous une liste complète de concasseur d’occasion à vendre sur Mascus. Cliquez sur marque de concasseur pour afficher les annonces de concasseur d’occasion par marque, ou veuillez utiliser les filtres sur la gauche de cette page pour trier les annonces de concasseur d’occasion par prix, par pays, par année, etc.. Les concasseurs sont d’imposants engins de

fabricant de matériel de carrière de gypse

Grande carrière de pierre écrasante à Navi Mumbai.concasseur à Navi Mumbai de 2014 une nouvelle technologie de Équipements d'exploitation du Minerai de Gypse Le concasseur de gypse est un équipement de concassage important utilisé pour écraser le minerai de gypse de grande taille en de petites particules.Fabricant de groupe de.FRADEM ...

Concasseur C60 à mâchoires pour recycler les matériaux de

Le Concasseur à Mâchoires réduit les pierres, les matériaux provenant de carrières, les gravats de démolition et d’excavation en petites pierres.. Les mâchoires ajustables permet de régler la granulométrie des produits concassés. Ainsi il valorise les déchets pour ensuite les recycler : recyclage des matériaux de construction, pierre, parpaings, marbre, tuiles, granit, goudrons

Les concasseurs - Qu’est-ce qu’un concasseur?

Un concasseur mobile est une machine de concassage de pierres couramment utilisée dans les secteurs de la construction et de l’exploitation minière pour traiter des matériaux durs tels que les pierres et les minerais en morceaux plus petits.. La principale caractéristique des concasseurs mobiles est leur portabilité, ce qui permet de les déplacer vers différents endroits sur le site ...

Concasseur à mâchoires de matériaux de démolition et gravats

Un premier mouvement de compression de gauche à droite, afin de concasser le granulat. Et un second mouvement de friction du haut vers le bas. Les mouvements répétitifs de la mâchoire mobile brisent la roche en petites pierres. Le concasseur à mâchoire reste de très loin le concasseur le plus populaire dans le monde.

Comment choisir votre concasseur - hellopro

Le concasseur giratoire séduit par structure simple et facile à opérer, mais également par son prix d'opération relativement bas. Il est utilisable aussi bien en concassage primaire qu'en concassage secondaire. Grandement utilisé dans les mines et les usines de traitement du minerai, cet équipement fonctionne selon le même principe que le modèle à mâchoire.

Matériel d’occasion pour carrières : Concasseur, Crible, Broyeur

Les marteaux permettent de traiter des gravats, béton (non armé d’acier), marbre, gypse, verre etc. Nous proposons également des matériels fixes comme avec le Komplet M5000. ... L’alternative à l’achat de concasseur d'occasion : la location

Mini concasseur CR400 CR600 CM Power - Pacamat

Mini concasseur cr400 et cr600 de la marque CM POwer disponibles chez PACAMAT Equipement, ... La solution idéale pour le recyclage de matériaux inertes, de démolition de petites tailles, gravats, fouilles, pierres naturelles, roches, tuiles, déchets de marbre, parpaings, briques.

Concasseur occasion à vendre - Achetez votre matériel TP

Concasseur. Le concasseur est un engin utilisé dans les mines et les carrières pour broyer et réduire des roches en granulats, qu’il s’agisse de calcaire, de grès, d’ardoise, de granit ou de marbre.. Il existe différents types de concasseurs : les concasseurs giratoires, les concasseurs à mâchoires et les concasseurs à cône qui travaillent par écrasement des minerais, et les ...